傳統典型舊潮汐給液方式,一般需要耗費較大動力且多量儲水的迴流槽配置,水位的升降則必須仰賴機械式的連續定時循環回流動作,灌排液操作亦無法同時均勻的控制大面積內每只單位缽盆的養水份飽和程度,以及植物本身的正確需求量,加上地下部的病蟲害極易蔓延和養液的變動性大等考量,使其與湛液方式同樣存在合理性低的長遠推展阻力。

自主潮汐式養液栽培系統(Autopot Systems®)在歷經多次改良後,最新一代的設計於專業栽培的領域上融入更簡易且更精準的技術,賦予了投資生產上更高的效率與質量。其設計概念,主要雖基於潮汐式的原理,但亦融合了浮根和毛細管式的水耕技術,巧妙的利用各型特殊不同壓力的專利人工智能閥Smart-valve MK系列~等來左右給液的進行。

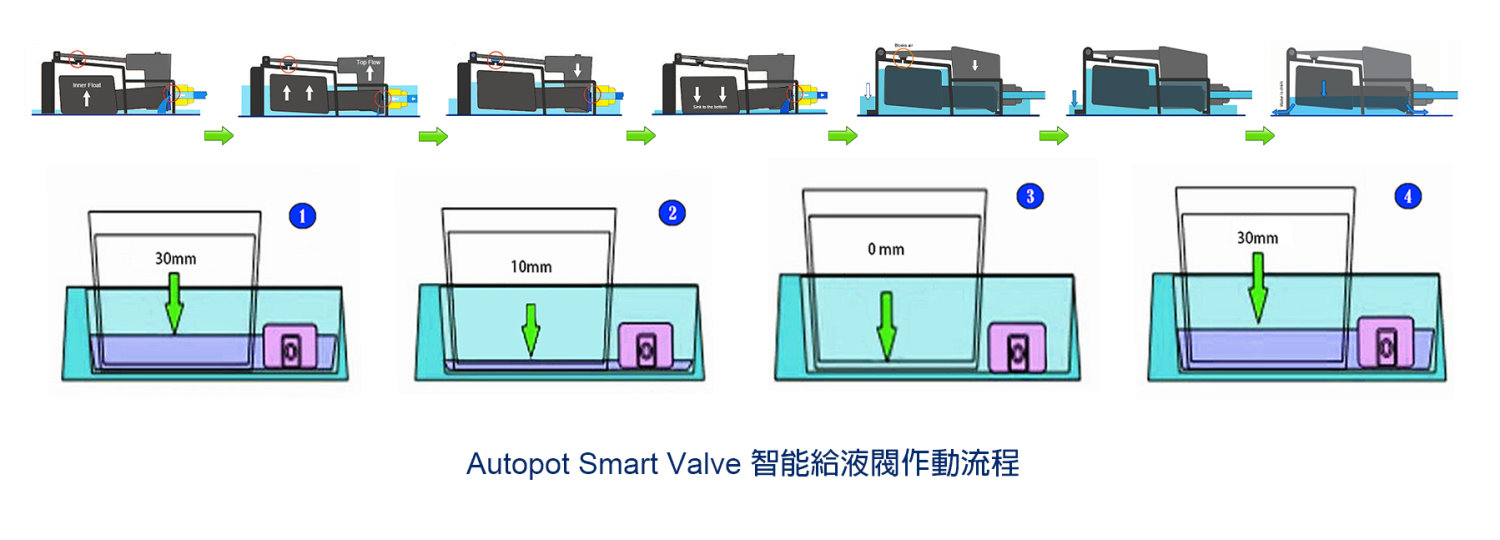

每一組栽培單位皆仰賴此套雙點式的水位控制以保持3cm左右的底床液面。當營養液受到植物根部吸取或是自然蒸散的消耗時,液面則隨之逐步下降,機制上必須等待底床液面呈現無水0cm,也就是養液完全被用盡後才會再度進行自動補充作業,使其水位重回3cm的狀態;而在0~3cm之間的緩衝地帶與自主式灌排液時間的進行中,則提供非常有利於地下部氧氣與養份的交換吸收條件,根部生長及地上部發育皆明顯優於一般慣用的循環水耕方式。

此一進化的設計更能夠促進植物的成長自然化以及介質保水狀態的精密掌握,令Autopot Systems®可以完全跳脫所有目前養液栽培技術的舊式框架,而形成獨樹一格的系統,其作動流程與模式實現了四項與眾不同的效能:

◆ 不排液→ 無環境污染的憂慮,養水份完全吸收利用。

◆ 不循環→ 獨立單位給液設計,阻隔地下部病蟲害的蔓延。

◆ 不回收→ 減少養液的後處理,PH與EC等幾乎不需調整。

◆ 不耗能→ 採自動或重力無動能給液,實現節能減碳目標。

換言之,栽培時的植物若處於飽水狀態,則系統不會提供不必要的養水資源,其需求完全取決於植物本身的”自體驅動”,也就是Plant Driven運用的原則,栽培床內隨時保持最新鮮的營養液。且水源的供給直接借用自體水壓力或是高點重力的連結,無須動力或只需微量能源即可達到精準的澆灌動作,加上超低故障與阻塞率的架構,使投資生產者從一開始的簡易組裝工程到實際栽培操作時的水、電、肥料等成本都能大幅度的縮減;其配置上也只要極小型的養液槽,無需地底管線埋設的繁雜施工。在Autopot系統種植下的作物,地下部溶氧充足無虞,可採取無介質的純水耕或是搭配各式介質的有機方式來進行,其由下往上的毛細管吸水構造比起點滴方式較無鹽類蓄積的問題。加上獨立基床式的水平調整容易,可高架、可平舖,省去大規模的整地工程;不止設施內,甚至包括戶外露天的栽培形式亦能夠勝任。對於偏遠供電困難或不足的地區,也只需連接小型太陽能板,12V超低耗電量的控制系統更為傳統典型的養液方式所相形見絀。

一般精密設施農業大都需投資高價的儀器,使用上總難以避免繁瑣的維修、調整、校正等手續,像是日射器、水位計、定時器、水份pF計以及多量的電磁閥和複雜的電腦程式等,這些過度機械化的裝備,皆有可能在突發的故障過程中造成專業大面積生產上的損失;而自主潮汐式Autopot系統有別於其他調控機制的特色,則不會受限於此一缺失,在任何情況下,皆可充分展現出省用水、省肥培、省能源、省勞力的特質與優點。

《“Plant Driven” Concept》:

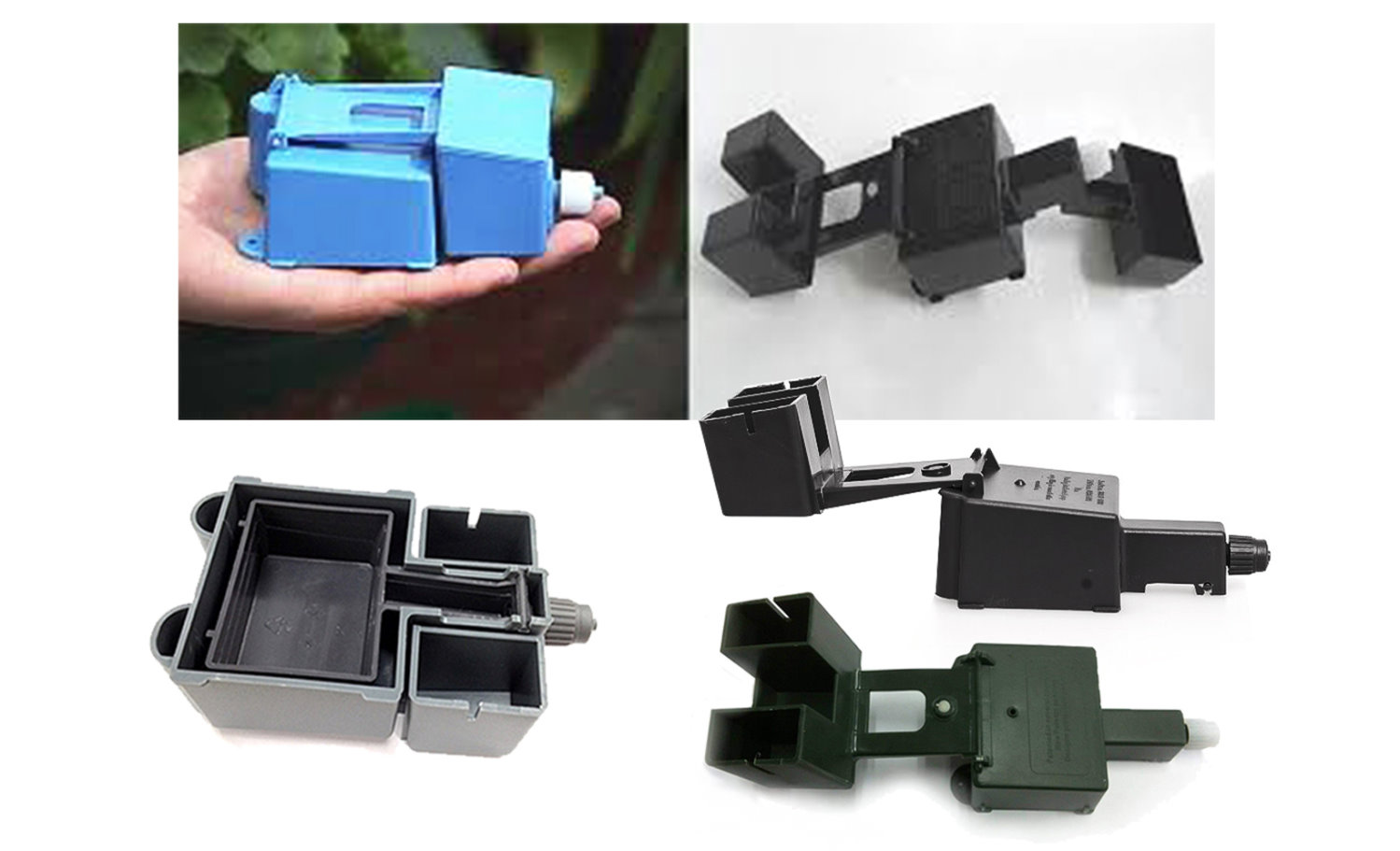

The Smart-valve is the heart of the Autopot Systems. It is this which controls the entry of the water to the reservoir. The original Smart-valves were used on Jim’s gloxinias, which were soil based plants and the results were excellent. In the thirty years of trials and refinement that have gone into today’s Smart-valve, most casual observers would be hard pressed to notice any difference, although any engineer would soon recognise the refinements. Today’s principle remains exactly as it was from day one and the main changes have been to fine tune performance rather than to alter working principles. Soon after its invention the trials of the Smart-valve were widened to encompass hydroponic with results being little short of spectacular although to many hydroponic enthusiasts, the results have been at variance with their fundamental beliefs about how a hydroponic system operates.

It is small enough to fit on the palm of your hand, mainly plastic construction and consists of two chambers. Its very nature makes it a comparatively low cost item which is very important because its low cost is what makes it practical to have a valve for each individual container and this is the very crux of the system’s versatility. It has several patents filed as many of the world’s main growing countries and the exact details of its operation are ones that we do not freely reveal. It is different to the conventional ball cock type of float valve because it allows total reduction of the fluid level before it refills. It is a real revolution in the way it allows water to be applied.

When connected to a water supply (which can be from either pressure reduced mains or tank) the valve opens to allow water to enter the bottom of the growing container to a pre determined and pre set depth (usually 30~35mm). The valve then closes and will permit no further water to enter the container until all the original supply has been conveyed from the water chamber to the pot and consequently to the plant. This absorption is achieved by capillary action that naturally occurs in the growing medium. Once the water has been absorbed to the extent that the film of water under the valve has gone, the valve re-opens and another supply of water enters the growing container. This is how the damp and drying out cycle occurs.